Menu

Reforming of damaged threads

- Complex work process: Replacement of the entire component

- Time-consuming: entire assemblies have to be disassembled to gain access to the thread

- High costs: Purchase of spare parts, which are also not immediately available

- Safety risk: Dynamically loaded threads should not be repaired by recutting. The thread’s load-bearing capacity is significantly reduced.

- Liability risk: If the manufacturer specifies a torque to achieve a certain pre-tensioning force, this only applies to undamaged threads. The force ratios change fundamentally during chip removalrepairs.

- Applications: Regular damage to wheel bolts, axles and stub axle turbine shafts, machine spindles and many more.

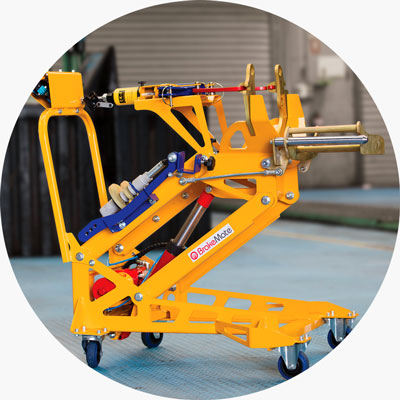

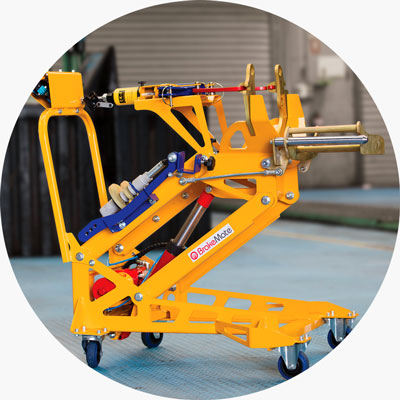

ReforMate XR-16

ReforMate XR-60

ReforMate XR-120

Benefits of ReforMate™

- Thread restoration with full material retention

- Consistent load capacity after restoration

- Proven in many safety-relevant areas of application

- Rapid amortisation of tool costs

- Efficient repair in the shortest possible time, even in the case of severe damage

- Very good performance thanks to high-quality profile rollers with a low tolerance range in continuous use

- High durability thanks to the best materials (100% stainless steel and hardened up to 60 HRC)

- Already in use as a problem solver at many OEMs

ReforMate™ in detail

Distribution

Tulip is the distributor for ReforMate within Australia, New Zealand and Asia.

Please contact us for all enquiries relating to this product.

Contact us today for a quote

CONTACT USTulip Corporation Pty Ltd, 1 Apollo Drive, Hallam Victoria 3803 Australia

- Telephone: +61-3-9796 3133

- Fax: +61-3-9796 4933