BrakeMate®

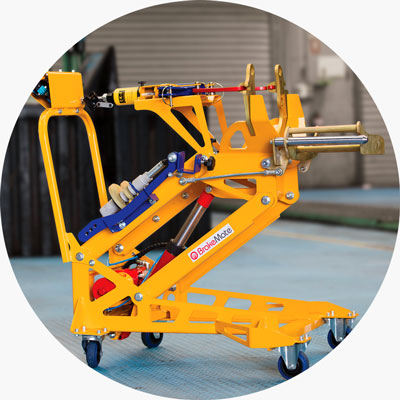

BrakeMate has been designed as an elevated service platform for servicing heavy vehicle disc brake assemblies; it eliminates all manual lifting during the disc brake maintenance process and substantially reduces service time and in turn saves $’s.

Key benefits

- Eliminate manual lifting of Calliper, Hub and Rotor

- Reduce the risk of back injury

- Ideal work height

- Reduce service time

- Specially designed for bus, truck and trailer maintenance needs

- Reduce maintenance times and costs

- Easy to use and offers major OH&S benefits

- Australian designed and manufactured

- Drum brake adapter option available

About BrakeMate®

BrakeMate is designed to protect workers from musculoskeletal injuries by removing the requirement for manual lifting. Many mechanics have suffered back injuries through manually handling rotor and hub assemblies weighing up to 70kg. Not only are these injuries painful for workers but they also cause financial pain for employers through lost time and Work Cover claims. Not all injuries are immediately apparent, either. Accumulative damage to the spine and joints over many years often leaves older workers with aches and pains that can prevent them from continuing in a hands-on role through to retirement age.

With BrakeMate mechanics no longer have to call for assistance with the lifting of heavy components. The whole process is a one-person operation and servicing times are greatly reduced, by more than 50 per cent in many cases. These labour savings mean the purchase costs of the BrakeMate system can be recovered over a short period of time.

The BrakeMate rotor/hub trolley is operated by an air-overhydraulic system. Although potential pinch points have been engineered out of the product, a three-button configuration of ‘Safety’, ‘Up’ and ‘Down’ ensures the operator’s hands are kept away from moving parts. BrakeMate allows for the quick and easy removal of the caliper utilising an adjustable clamp mechanism. This easily fits calipers mounted anywhere in the three, nine and 12 o'clock arc position. An adaptor is also available to suit calipers mounted at the six o'clock position. The rotor/hub trolley locates onto the studs. Adaptor plates allow for connection to common 10-stud and eight-stud patterns. A manual hydraulic ram separates the hub assembly from the vehicle. The use of a manually operated ram allows the operator to have a feel for the force being applied.

Once removed from the vehicle, the two trolleys are mated together. BrakeMate then easily separates the rotor from the hub. The used rotor is rolled onto the rotor rack, the ‘Lazy Susan’ mounted rack is then rotated through 180 degrees to allow the new rotor to be rolled into position. The unit is then easily refitted to the vehicle.

The Distributors

|

Finnegan Equipment Solutions Ltd Lusk Co. Dublin Ireland 00353872669071 |

Xpertive 53 Avenue Carnot Bâtiment K19 69 250 Neuville Sur Saone FRANCE +33 (0)6 95 77 45 96 |

SOSNOWSKI Sp. z o.o. Sp. k. Marynarki Polskiej 55E, 80-557 Gdańsk, POLAND phone: +48 58 76 13 500 |

|

Premier Pits Town Drove, Quadring Spalding Lincolnshire PE11 4QP ENGLAND T: 01775 821 222 |

Vehicle Inspection Systems 6317 McCoy Road, Suite 110 Orlando, Florida 32822 USA Phone: 407-206-3615 |

GAMMATEST 220045 Minsk, Churlionisa St, 4, Room 172 REPUBLIC OF BELARUS +375 (29) 189 688 60 |

|

JM Company 312-15, Jaedurumi-gil Paju-si Gyeonggi-do 10863 REPUBLIC OF KOREA +82 31 944 7670 |

Myers Marketing (1981) Ltd Dotan 2, ET Yavneh ISRAEL +972 03-558 1430 |

EUROPART MATERIALS GmbH Onur Algan Hansering 1 59457 Werl GERMANY Phone: +49 2331 3564 4503 |

|

EUROPART DANMARK A/S Tom Holmskov Olesen Værktøjsafdelingen Kokmose 14 DK-6000 Kolding Phone: +45 7010 0080 |

Contact us today for a quote

CONTACT USTulip Corporation Pty Ltd, 1 Apollo Drive, Hallam Victoria 3803 Australia

- Telephone: +61-3-9796 3133

- Fax: +61-3-9796 4933